from Nano One Materials Corp. (NASDAQ:NNOMF)

Nano One Provides Corporate Update

Highlights:

Demand for Nano One's One-Pot™ LFP technology solution is building across three core market application segments-defence & national security, energy storage systems (ESS) and electric vehicles (EVs).

Nano One's Candiac lithium iron phosphate (LFP) demonstration plant is central to its commercialization strategy, driving toward first production and revenue generation while supporting the growth of its technology solutions and licensing business.

Public policy and multi-use demand are driving the need for localized LFP cathode active materials (CAM) production in different parts of the world outside of Asia.

VANCOUVER, BC / ACCESS Newswire / February 18, 2026 / Nano One® Materials Corp. (TSX:NANO)(OTCQB:NNOMF)(Frankfurt:LBMB) ("Nano One" or the "Company"), a process technology company specializing in lithium-ion battery CAM, is pleased to provide a corporate update and an outline of its key strategic objectives for 2026.

To view this release in its original stylized PDF Click Here

Business Development & LFP Market Opportunities

Global battery demand continues to grow, with LFP chemistries capturing an increasing share of that growth, representing roughly half of global cell demand in all applications and also the dominant chemistry in the ESS market segment, accounting for over 90%1 of installations. North America is emerging as a key growth region, where LFP is gaining share in grid storage, data-center and cost-sensitive EV applications.

This shift is reflected in a rapidly expanding LFP project pipeline. In the United States, planned LFP capacity increased from about 180 GWh to nearly 290 GWh in 2025, driven by a mix of new projects and the retooling of existing NCM gigafactories2 - this will require a supply of more than 600,000 tonnes per annum of LFP CAM. In Canada, the emerging lithium battery cell-manufacturing base is also moving towards LFP, creating domestic supply chain opportunities for One-Pot LFP cathode production. Investments in these projects span multiple markets globally where customers and governments are looking to establish regionalized domestically-secured supply chains.

Alex Holmes, President and Chief Strategy Officer, said, "Nano One's LFP demonstration production plant in Candiac, Québec is being developed as a stepping stone to first revenue-initially targeting customers whose qualification requirements and volumes are aligned with Candiac's scale and capacity. Candiac also enables product sampling, de-risking and development work to be undertaken for much larger facilities and technology licensing opportunities. We are targeting initial commercial LFP supply agreements for defence and energy-storage applications by the end of 2026."

Nano One continues to advance its partnership with Sumitomo Metal Mining for the commercialization of its technology and with Rio Tinto for qualified large volume lithium carbonate supply. The partnership with Worley Chemetics continues to develop LFP CAM Package technology solutions and the initiative with the Arkansas Lithium Technology Accelerator (ALTA) is focused on promoting US-based LFP CAM plant opportunities. Engagements with lithium battery cell manufacturers, automotive OEMs, raw-material suppliers, equipment vendors, engineering firms and government agencies also continue to advance, with counterparties at various stages of qualification and commercial discussions.

Candiac: First Revenue and Demonstration Plant

Denis Geoffroy, Chief Operating Officer, said, "Our LFP production facility in Candiac, Québec is central to our commercialization efforts and our growth initiatives. The piloting and demonstration lines enable a staged approach that is deliberate, lean and optimized for productivity. It aligns capital spending with real demand and allows for demonstration of performance to customers, as well as potential strategic and financial partners."

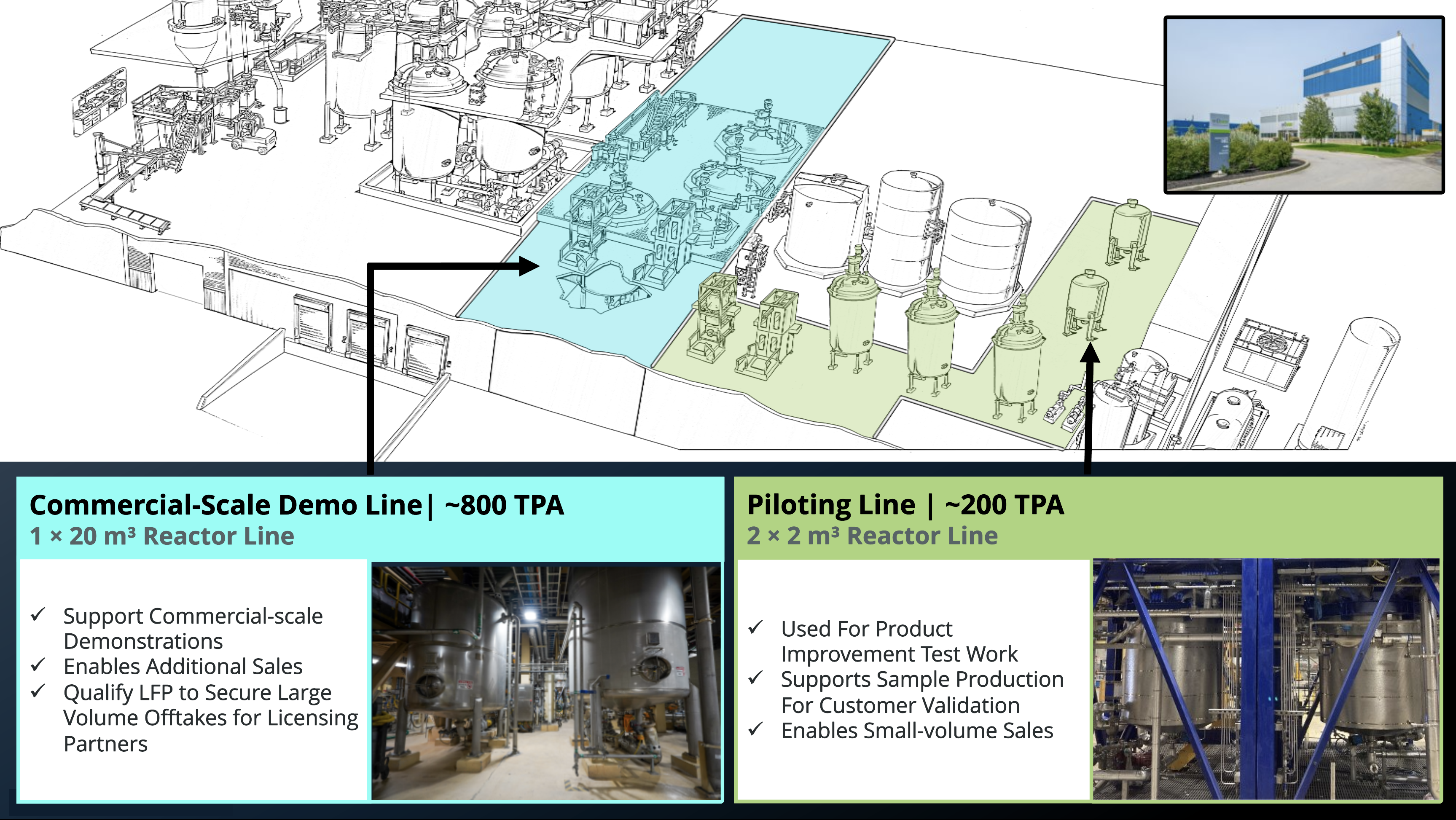

Image: Nano One's LFP CAM facility in Candiac, Québec illustrating pilot and full-scale demonstration production lines.

The Pilot Line of ~200 tpa is already operational for customer sampling, continuous process and product improvement, and small commercial sales, with first commercial agreements targeted for end of 2026.

The Demonstration Line is currently being operated manually in a full-scale reactor, with automation improvements underway to enable ~800 tpa of commissioned capacity targeted in the first half of 2027. This line will be focused on producing LFP cathode materials, growing commercial sales and demonstrating full-scale One-Pot reactors fully automated and integrated with material drying, calcining and packaging processes.

The Demonstration Line also supports the volumes required for A-, B-, and C- sample product qualification with large cell producers looking to secure future supply through offtake agreements from large scale LFP facilities enabled by Nano One's One-Pot technology.

Design-One-Build-Many Licensing Growth Strategy

Nano One is pursuing a licensing growth strategy to address the emerging global need for supply chain and processing alternatives that enable diversified LFP ecosystems, localization and resilience. Its One-Pot technology solution is marketed directly to existing CAM producers, who are potential licensees, looking for LFP cathode materials solutions that can deliver a technological edge, cost-competitive process and are an industrial solutions partner that can drive growth and scale in emerging markets around the world.

Nano One is also developing a more complete technology offering, through its partnership with Worley Chemetics and their colleagues at Worley Comprimo. Collectively, the Technology Solutions group at Worley has more than 100 years of experience designing, selling and delivering chemical processing technology solutions globally. They hold significant market share in their respective segments and joined Nano One in Candiac in January to collaborate on 2026 strategic planning.

The Design-One-Build-Many approach includes a commercial-ready One-Pot LFP CAM Package that is targeted for completion and marketing in H1 2026. This provides an inside battery limits (ISBL) offering, which is essentially the "guts" of a One-Pot LFP production-line, engineered to a class 3 cost estimate. It also includes a preliminary process design package and qualified vendor quotes for key equipment, providing enough definition to promote this technology stack to a global target-customer base.

Capital and Financial Discipline

In December 2025, the Company completed an equity financing to fund the next phases of production and licensing plans. This financing provides the upfront capital needed to advance Candiac expansion and related projects and allows Nano One to draw down contracted government funding and extend its financial runway.

Carlo Valente, CFO, said, "This financing complements our non-dilutive sources of capital achieved to date, including government funding, the Candiac sale and leaseback transaction and our sale of vacant land. Over $63.0 million of non-dilutive capital has been secured since the beginning of 2024, and as of September 30, 2025, Nano One had $17.8 million in cash. Subsequent to September 30, 2025, the Company completed a capital raise for $7.0 million in gross proceeds and was also awarded $5 million from NRCan to support the Candiac expansion plans. As of December 2025, the Company had $25.8 million in undrawn government funding available."

Nano One's at-the-market (ATM) program has been used modestly since launch and represents a low-cost source of funding and a small portion of overall trading volume, with detailed results reported in quarterly and annual filings.

Public Policy, Dual-Use Demand and "Why Now"

Government policies, customer demand and supply chain strategies are now aligned in favour of localized LFP cathode production.

"The Government of Canada is proud to support Nano One as they scale up their made-in-Canada battery innovation. At a time where the global demand for batteries is surging, their work could not be more important. We are showing the world how to build cleaner, more secure, and more sustainable supply chains. This patented technology, developed here at home, is helping position Canada as a global leader in the next generation of battery materials-proving that Canada can power the world."

- The Honourable Tim Hodgson, Minister of Energy and Natural Resources

Governments in key jurisdictions for Nano One-including Canada, the United States, Europe and the Indo-Pacific region-have prioritized critical minerals and their derivatives, including battery materials for lithium-ion batteries. LFP cathode materials specifically is increasingly reflected in government policy-making and funding decisions because of its importance for energy storage, defence and EVs. In 2025, EV sales slowed in the United States but reached record highs in the European Union, alongside strong demand from LFP battery applications in data centers.

Adam Johnson, Senior Vice President External Affairs, said, "These market trends and emerging policies reinforce Nano One's engagement with key decision-makers, supported by on-shoring efforts and actions across multiple markets globally outside of Asia, which are all looking to grow local domestic, resilient and sustainable supply in each of their respective regions."

Policy measures, such as the 2025 U.S. National Defense Authorization Act (NDAA) prohibit batteries and battery components being procured from Prohibited Foreign Entities (PFEs) for the U.S. military starting in 2028, while the U.S. Congress has maintained the 45X manufacturing tax credit at $35/kWh. Together, these incentives align with one of Nano One's key focus markets, the U.S, to develop localized production of LFP batteries and cathode material inputs. NATO defence-spending commitments and dual-purpose defence-civilian strategies support localized supply chain ambitions under the 2% and 5% commitments. G7 actions on diversifying critical minerals through the Critical Minerals Production Alliance are also pushing supply chains toward allied jurisdictions and away from single-country dependence. Nano One's One-Pot technology solution is designed for this world: it is cost-competitive, simplifies supply chains, reduces waste and is supported by regionally sourced input materials.

2026 Strategic Objectives

The Company is entering the year 2026 having advanced the main catalysts set out a year ago: Its Candiac facility is moving toward revenue, the CAM Package is approaching a go-to-market state and the balance sheet is structured to support the next phase of execution. Against this backdrop, Nano One's key areas of focus in 2026 are:

Product Sales: Advance customer qualifications at Candiac toward initial commercial sales and multi-year purchase commitments, continue product and process improvements and report on scale-up and optimization of Candiac production capabilities.

Technology Licensing: Finalize and market the CAM Package as a ready-to-license One-Pot LFP ISBL design to strategic targets and continue customer engagements for technology license-only sales.

"We have laid the groundwork," said Nano One CEO Dan Blondal, "and we are focused on execution, converting target customer engagement into commercial sales of product and technology and building a recurring revenue base through licensing and royalties that drives long-term shareholder value."

####

About Nano One

Nano One® Materials Corp. (Nano One) is a process technology company changing how cathode active materials (CAMs) are produced for lithium-ion batteries. Nano One's platform is built on a portfolio of patented processes, decades of manufacturing know-how and modular plant designs that enable scalable, cost-competitive and easier-to-permit CAM production with resilient supply chains. The technology eliminates wastewater and byproducts while enabling regionally sourced raw materials and reducing exposure to foreign supply chain volatility. Modular plants are designed with fewer steps to reduce capex, energy and environmental intensity and to accelerate deployment, manufacturing and licensing. Product development and process optimization are based at Nano One's Innovation Centre in Burnaby, British Columbia while piloting, demonstration and commercial production are based in Candiac, Québec, supported by a team with more than 15 years of commercial cathode manufacturing experience supplying global cell manufacturers. Strategic collaborations with global partners including Sumitomo Metal Mining, Rio Tinto and Worley support Nano One's Design-One-Build-Many growth strategy. Nano One has received funding support from the Governments of Canada, the United States, Québec and British Columbia.

For more information, please visit nanoOne.ca.

Company Contact:

info@nanoone.ca

+1 (604) 420-2041

Cautionary Notes and Forward-Looking Statements

This press release may contain statements that may be deemed to be "forward-looking information" and "forward-looking statements" within the meaning of applicable securities legislation. All statements, other than statements of historical fact, included herein are forward-looking information, including, but not limited to statements regarding: revenue generation; operational growth; sales, licensing and offtakes; government funding; incurrence of costs; competitive conditions; general economic conditions; the development of technology, supply chains, and plans for construction and operation of cathode production facilities for acceptance of the Company's product and licensing packages; the timing, completeness and commercial readiness of the Company's technology packages; the continuation, implementation or effectiveness of government policies, incentives, tax credits or procurement frameworks supporting localized battery supply chains; industry acceleration and demand; successful current and future collaborations that are/may happen with OEMs, miners or others, as well as the performance, contributions and deliverables of strategic partners and collaborators; the value, functions and intended benefits of the Company's technology and products; efforts to build resilient and sustainable supply chains for critical minerals and battery materials; the development and evolution of Nano One's technology and products for scale up and commercialization; achieving commercial production of LFP; the purpose for expanding the Candiac facilities and scalability of developed technology including production capacity targets, commissioning timelines and operational milestones for the Candiac facility; successful completion of customer product qualification programs, testing, validation or certification processes; and the execution of the Company's current and future plans - which are contingent on capital support and grants. Generally, forward-looking information may be identified by the use of forward-looking terminology such as 'believe', 'expect', 'anticipate', 'plan', 'continue', 'estimate', 'may', 'will', 'should', 'ongoing', ‘target', ‘goal', ‘potential', 'expects' or 'does not expect', 'proposed', 'is expected', 'budget', "scheduled", 'estimates', 'forecasts', 'intends', ‘anticipates' or ‘does not anticipate', or variations of such words and phrases, or by the use of words or phrases which state that certain actions, events or results may, could, would, or might occur or be achieved. This forward-looking information reflects Nano One's current beliefs and is based on information currently available to Nano One and on assumptions we believe are reasonable. These assumptions include, but are not limited to assumptions regarding: contracted projects; revenue generation; operational growth; licensing and offtakes; government funding; incurrence of costs; competitive conditions; receipt of the total amount of announced anticipated funding from collective government programs; use of proceeds; general and global economic and regulatory changes; next steps and timely execution of the Company's business plans; the development of technology, and plans for construction and operation of cathode production facilities; risks associated with scale-up, commissioning, process performance and industrial implementation of new manufacturing technologies; the timing, completeness and commercial readiness of the Company's technology packages; the continuation, implementation or effectiveness of government policies, incentives, tax credits or procurement frameworks supporting localized battery supply chains; successful current or future collaborations that may happen with OEMs, miners or others; the execution of the Company's plans which are contingent on capital sources; the Company's ability to achieve its stated goals; the commercialization of the Company's technology and patents via license, joint venture and independent production; the Company's efforts to build resilient and sustainable supply chains for critical minerals and battery materials; anticipated global demand and projected growth for LFP batteries; and such other risk factors and risks as disclosed in the Prospectus Supplement, Base Shelf Prospectus, the Company's most recent annual information form, management's discussion and analysis and other documents filed from time to time under the Company's profile on SEDAR+ at www.sedarplus.ca. Forward-looking information is subject to known and unknown risks, uncertainties and other factors that may cause the actual results, level of activity, performance, or achievements of the Company or its subsidiaries to be materially different from those expressed or implied by such forward-looking information. Such risks and uncertainties may include but are not limited to prevailing capital markets conditions, general business, economic, competitive, political and social uncertainties, changes in legislation, and lack of qualified, skilled labour or loss of key individuals. Although the Company has attempted to identify important factors that could cause actual results to differ materially from those contained in forward-looking information, there may be other factors that cause results not to be as anticipated, estimated, or intended. Accordingly, readers should not place undue reliance on forward-looking information. The Company does not undertake to update any forward-looking information, except in accordance with applicable securities laws.

1 Data from Benchmark's Battery Tech Expo 2025: Europe's Drive for Cathode Independence.

2 Data from Benchmark's Mine to Grid: 2025 Year in Review.

SOURCE: Nano One Materials Corp.

View the original press release on ACCESS Newswire