from Tectonic Metals Inc. (isin : CA87877T3010)

Tectonic Reports Gold Recoveries to 96.8% from Coarse Crush Bottle Rolls Warranting Investigation into Heap Leaching

VANCOUVER, BC / ACCESSWIRE / February 16, 2023 / Tectonic Metals Inc. (TSXV:TECT)(OTCQB:TETOF)(FSE:T15B) (the "Company" or "Tectonic") today announced metallurgical test results from the Company's Flat Gold Project ("Flat"), an intrusion-hosted, bulk tonnage gold system located in southwestern Alaska. As part of the Company's first year exploration program at Flat, metallurgical samples were selected by Tectonic from historically drilled diamond core determined to be representative of the known drilled mineralization and five composites comprising of four oxide and one fresh sulphide were formed. The composites were then subject to conventional bottle roll, gravity, combined gravity and bottle roll and flotation metallurgical test work with the goal of de-risking the project and to provide insight into what metallurgical processing methods might be ideal. The metallurgical results from the five composites returned gold recoveries averaging 95.6%, with one test returning a high of 99.1%, all with conventional cyanide leaching (bottle roll) of 75µm material. These exceptional results prompted Tectonic to conduct a follow-up bottle roll test at a coarser crush (6 mesh, 3360 µm), which potentially can be used as a proxy for heap leaching, and an average gold recovery of 88.5% was achieved with four of the five composites returning an average gold recovery of 94.0% and a high of 96.8%. The metallurgical results also demonstrate that the mineralization presently known at Flat is not grind sensitive, is extremely low in sulphur, non preg robbing and favourable to various gold extraction methods. The success of Tectonic' metallurgical program warrants investigating column leach testing as a next step to determine if the mineralization at Flat is amenable to heap leaching.

Tony Reda, Tectonic President & CEO, commented: We are very pleased with the results of our initial metallurgical testing at Flat, which undoubtedly demonstrates the non-refractory nature of known mineralization to date as evidenced by the exceptionally high gold recoveries through bottle roll testing with minimal cyanide consumption. The baseline test work clearly de-risks the Flat project with respect to metallurgy and gives Tectonic confidence to aggressively explore for and develop resources on the project. Most importantly, the high gold recoveries from the 6 mesh bottle rolls coupled with the fact that mineralization begins at surface significantly endorses the potential amenability for open-pit, heap leachable mineralization at Flat. Heap leaching is a processing and extraction technology becoming increasingly popular over recent years due to the potential cost advantages and lower environmental impact it can offer to miners especially as the average grade of gold deposits has decreased over the past decade. Tectonic is excited to evaluate heap leaching as a viable metallurgical processing method at Flat as the next value creating opportunity."

Metallurgical Highlights

- Conventional bottle roll tests with 48-hour leach kinetics of material ground to a K80 of 75 µm yields an average gold recovery of 95.6% with a range of 88.3% to 99.1%

- Conventional gravity + bottle roll tests with 48-hour leach kinetics of material ground to a K80 of 75µm yield an average gold recovery of 97.2% and a high of 98.7% across the 5 composites. The fresh sulphide composite yielded a highly favourable gold recovery of 94.7%

- Given the initial favourable results, Tectonic then elected to do a coarser crush (6 mesh coarse crush, K100 of 3360µm) bottle roll test on all five composites with leach kinetics over a 192-hour period as a proxy for heap leach amenability ahead of future column leach testing. Bottle roll testing on this coarser crush material achieved an average gold recovery of 88.5% with 4 of the 5 composites averaging 94.0% at 3360µm vs 97.5% at 75µm indicating the majority of the tested material is not grind sensitive

- Strong and rapid leach kinetics demonstrated throughout the various metallurgical tests

- Very low cyanide consumption with an average of 0.22 kg/t for both the 75µm bottle and 3360µm coarse bottle rolls tests

- Low sulphur content with 4 of 5 composites averaging 0.02% and 0.06% in the fifth composite

- No preg robbing identified

- The various metallurgical tests and their positive results indicate that Tectonic may have several metallurgical processing options available at Flat

- To learn more about the metallurgical program and view accompanying maps and images please click here. Please also see Tectonic's news release of September 07, 2022

Flat Metallurgical Program - Composites

Tectonic's Metallurgical Test Work Program focused on Flat's primary target known as the Chicken Mountain Zone ("CMZ") comprised of intrusion-related gold mineralization hosted within a zoned monzonitic intrusion, which forms part of the more extensive Late Cretaceous Flat volcano-plutonic complex intruding Cretaceous-aged Kuskokwim sediments. 55 drill holes (diamond and reverse circulation) were historically drilled at CMZ, all of which encountered gold mineralization. Five composites (four oxide and one fresh non-oxidized sulphide) derived from 41 samples collected from 9 drill holes for a total weight of 119 kilograms were formed and determined to be representative of the known gold mineralization at Flat. The five composites were then subject to an array of metallurgical testing, including bottle roll testing at various crush sizes, gravity testing, combined bottle roll + gravity testing and flotation testing, to provide insight on what metallurgical processing methods might be ideal going forward.

In total 5 composites were created from historic drill core samples taken from representative examples of mineralization from various intrusive phases, alteration assemblages and oxidation profiles within the two main historically drilled areas on Chicken Mountain. Composites were blended following geochemical characterization, fire assaying and cyanide shake tests of each individual sample. Table 1 summarizes each composite.

Table 1: Flat Metallurgy Composites

Composite | Zone | Samples | Drill Hole | Drill Hole Sample depth range (m) | Host Rock | Mineralization Type | Assayed Composite Head | ||

Au g/t | Sulphur % | Carbon % | |||||||

UFA | Upper Flat | 11 | 3 | 30-49 | Biotite Syenite | Oxide | 1.10 | 0.02 | 0.01 |

UFB | Upper Flat | 9 | 3 | 70-119 | Biotite Syenite | Oxide | 0.65 | 0.02 | 0.26 |

HCA1 | Main Chicken Mtn | 7 | 1 | 4-64 | Quartz Monzonite | Oxide | 0.53 | 0.02 | 0.02 |

HCA2 | Main Chicken Mtn | 6 | 2 | 26-41 | Quartz Monzonite | Oxide | 1.08 | 0.02 | 0.42 |

HCB | Main Chicken Mtn | 8 | 1 | 120-132 | Quartz Monzonite | Fresh-Sulphide | 1.14 | 0.06 | 0.42 |

Flat Metallurgical Program - Baseline 75um Metallurgical Test Work

Following gold (Au), sulphur (S) and carbon (C) head grade characterization of the 5 composites, aliquots were ground to K80 at 75µm and subjected to 1Kg tests for cyanide (CN) gold extraction (bottle roll), gravity concentration, combined gravity bottle roll and flotation recovery. Results of the 75µm test work are summarized in Tables 2, 3 and 4 below.

Table 2: 75µm grind 48 hr bottle roll tests

Composite | Mineralization Type | Calculated Head Grade | Consumption (kg/t) | Au Recovery % | |||||

Leach Kinetics (hour) | |||||||||

Au g/t | NaCN | Ca(OH)2 | 2 | 6 | 24 | 48 | Total | ||

| UFA | Oxide | 1.66 | 0.24 | 2.57 | 90.9 | 98.1 | 99.4 | 96.7 | 96.7 |

| UFB | Oxide | 0.68 | 0.19 | 1.23 | 90.4 | 98.8 | 101.6 | 97.1 | 97.1 |

| HCA1 | Oxide | 0.75 | 0.28 | 2.91 | 58.0 | 76.0 | 96.0 | 99.1 | 99.1 |

| HCA2 | Oxide | 1.05 | 0.17 | 2.89 | 84.5 | 96.7 | 95.8 | 97.0 | 97.0 |

| HCB | Fresh-Sulphide | 1.32 | 0.23 | 0.92 | 74.8 | 83.7 | 88.2 | 88.3 | 88.3 |

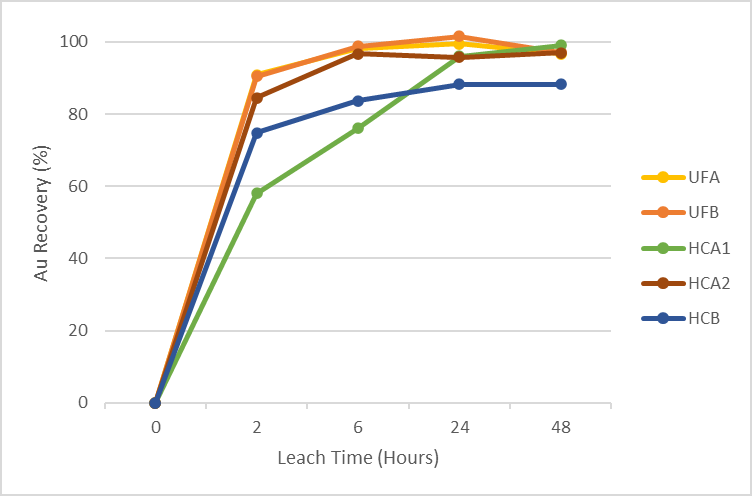

Bottle roll results in Table 2 above and below in Figure 1 show excellent Au recoveries through CN leaching for composites UFA, UFB, HCA1 and HCA2 which averaged 97.5% Au extraction after the 48-hour test. Composite HCB achieved a slightly lower Au extraction of 88.3%. Cyanide consumption for all 5 tests was low averaging 0.22 kg/tonne milled.

Figure 1. 48 Hour leach kinetics of 75µm grind bottle roll tests. Gold recoveries averaged 95.6% with a range of 99.1-88.3%.

Table 3: 75µm gravity gold concentration

Composite | Mineralization Type | Calculated Head Grade | Gravity Concentrate | |

Au g/t | Au g/t | Au Recovery % | ||

| UFA | Oxide | 1.16 | 192 | 35.8 |

| UFB | Oxide | 0.79 | 62 | 15.2 |

| HCA1 | Oxide | 0.61 | 81 | 12.7 |

| HCA2 | Oxide | 1.05 | 20 | 5.5 |

| HCB | Fresh-Sulphide | 1.13 | 409 | 43.7 |

Gravity Au recovery (Table 3) for composites UFA, UFB, HCA1 and HCA2 was low averaging 17.3% with an average gravity concentrate grade of 89 g/t Au. Composite HCB showed good gravity Au recovery of 43.7% with an excellent concentrate grade of 409 g/t Au.

Table 4: 75µm flotation

Composite | Mineralization Type | Calculated Head Grade | Concentrate Specs | Recovery % | |||

Au g/t | Wt. % | Au g/t | Ag, g/t | Au Rec % | S Rec % | ||

UFA | Oxide | 1.19 | 27.5 | 3.66 | 1.09 | 84.8 | 45.0 |

UFB | Oxide | 0.81 | 16.4 | 3.52 | 3.43 | 71.1 | 27.9 |

HCA1 | Oxide | 0.52 | 17.7 | 2.19 | 0.61 | 74.6 | 42.7 |

HCA2 | Oxide | 1.06 | 10.7 | 5.39 | 1.45 | 54.3 | 41.8 |

HCB | Fresh-Sulphide | 1.33 | 14.6 | 8.87 | 1.90 | 97.4 | 76.3 |

Flotation test work (Table 4) for UFA, UFB, HCA1 and HCA2 returned an average of 71.2% Au recovery and 39.3% S recovery, which suggests flotation may not be the best processing option for Flat oxide mineralization given the high gold recoveries obtained through conventional bottle roll and the combined gravity and bottle roll testing. Composite HCB, which comprised fresh sulphide mineralization, returned 97.4% Au recovery with 76.3% S recovery indicating excellent amenability for gold recovery through flotation of Flat sulphide mineralization.

Further test work of the K80 75µm grind comprising gravity concentration followed by bottle roll cyanide extraction of gravity tails was conducted specifically to address the high gravity recovery and lower bottle roll recoveries in composite HCB. Results of the combined gravity - bottle roll tests are summarized in Table 5.

Table 5: 75µm gravity + bottle roll

Composite | Mineralization Type | Calculated Head Grade | Gravity Concentrate | Bottle Roll | Au Recovery (%) | ||||||

Consumption (kg/t) | Leach Kinetics (hour) | Total | |||||||||

Au g/t | Au g/t | ||||||||||